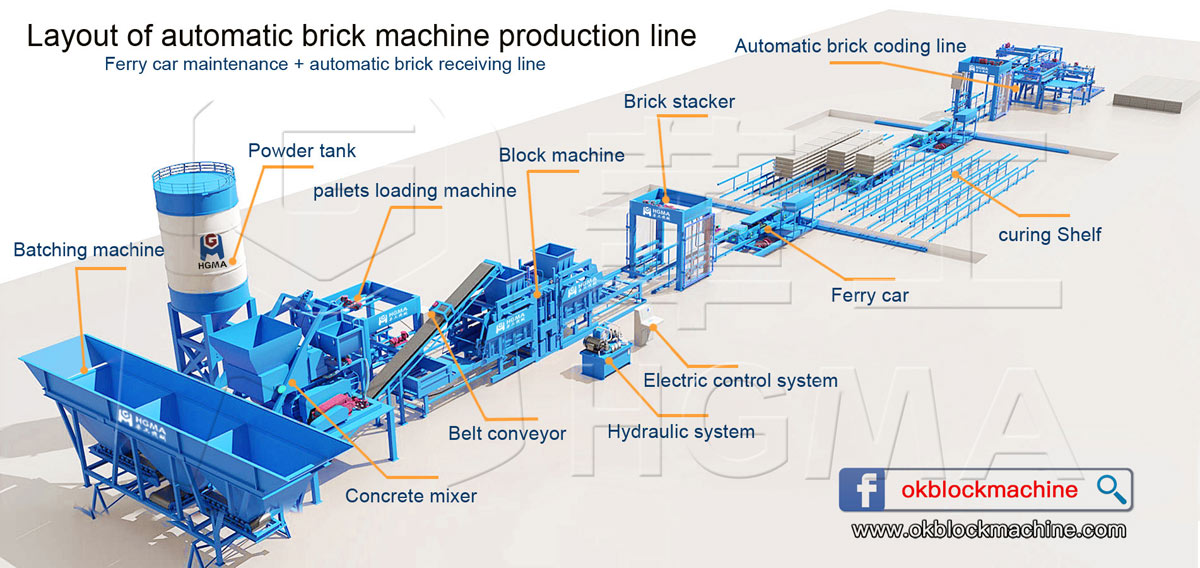

The automatic handling and maintenance line is to solve the labor and fuel consumption problems of forklift transportation in the subsequent process of the simple block brick production line, realize seamless connection with the simple block brick production line and intelligent code brick machine, form the whole process of block brick forming, maintenance and packaging, realize intelligent brick making, the mother ferry adopts servo drive positioning, and the handling trolley enters and exits the kiln, So as to realize steam curing.

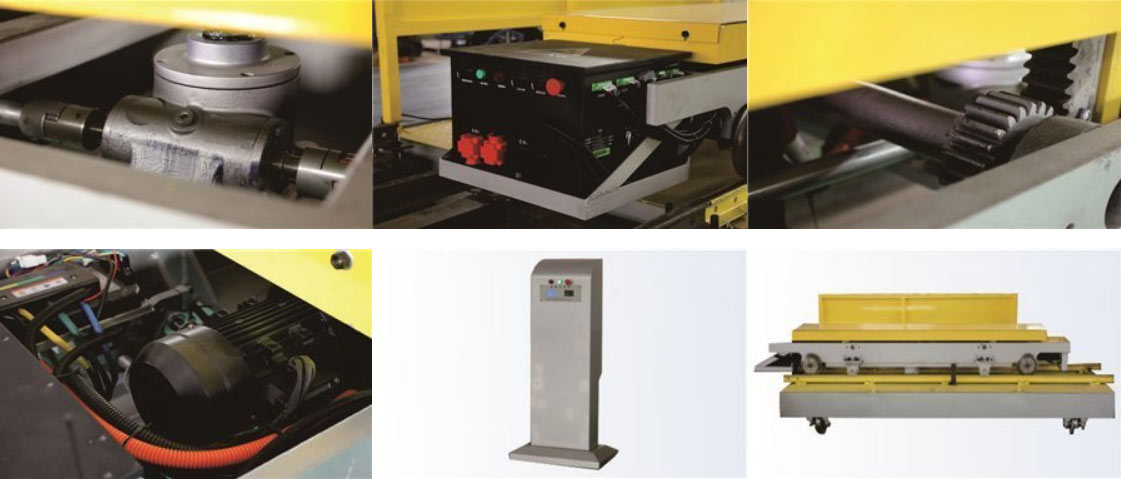

The whole set of sub bus is controlled by PLC + touch screen, and the equipment operation parameters can be adjusted at any time to observe the operation of each action. Cooperate with laser induction + intelligent sensor to realize unmanned automatic operation. In case of fault, it will automatically stop the alarm and display the fault location. It can easily eliminate the fault without professional technicians. Equipped with remote control system + cloud data equipment, manufacturers can solve problems in the office all the time.

3. Lithium battery power supply, the track does not need insulation, and the construction and maintenance are convenient.

|

|

4. Intelligent fast charger can automatically charge at the designated position when the power is low without manual operation.

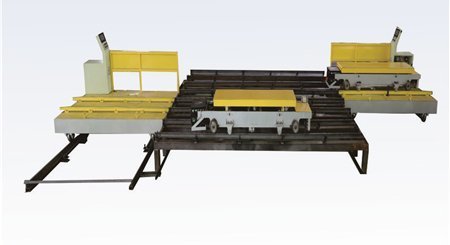

5. Single ferry can take multiple transporters to realize the same ferry in and out of the kiln. Leave A Message

Leave A Message