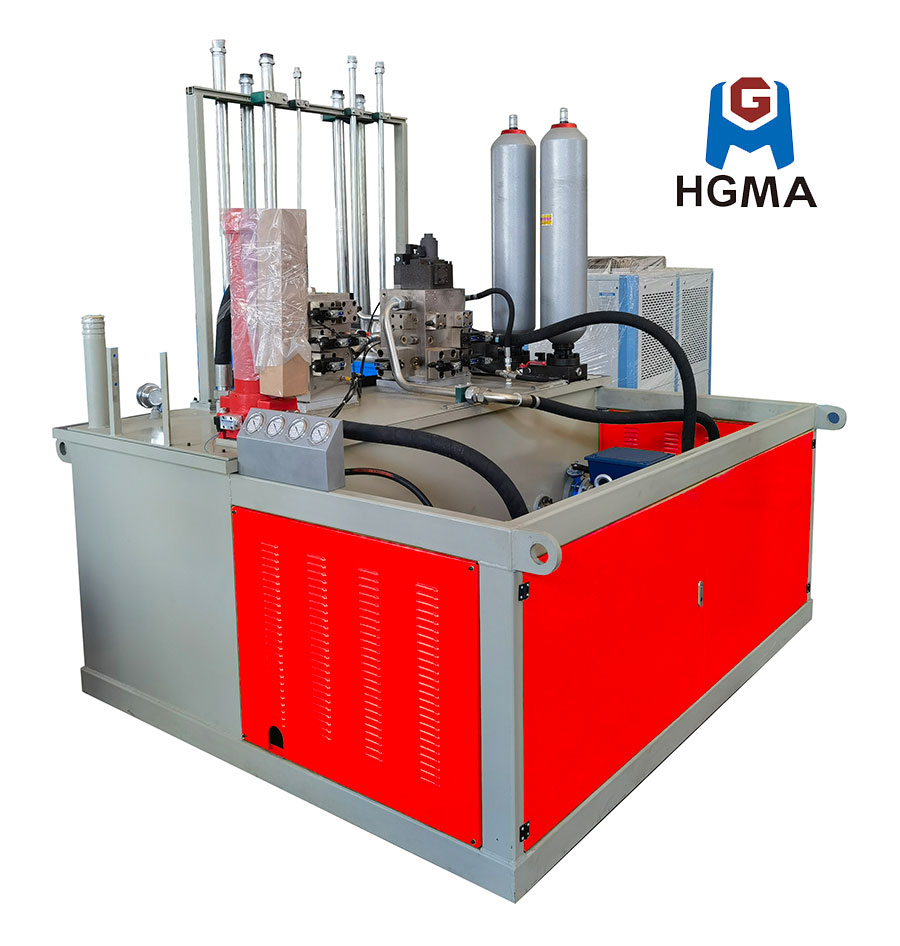

The hydraulic system is the main power system of the concrete block making machine, which can control the pressure and running speed of the machine. The hydraulic system includes main pumps, hydraulic cylinders, oil tanks, oil pipes and other components. The main pump is responsible for pressing the hydraulic oil from the oil tank into the hydraulic cylinder, thus controlling the pressure and speed of the bricks. The hydraulic cylinder is the core component of the machine, which is composed of a piston, piston rod, sealing elements and other parts. When the hydraulic oil is pressed into the hydraulic cylinder, the piston will be under pressure, causing the piston rod to move downward and compact the raw materials to form bricks.

HGMA's brick machine hydraulic station is very energy-efficient compared with the traditional brick machine hydraulic system. The servo system of the brick machine can output the maximum pressure but keep the speed close to zero during the stages of mold clamping, pressure holding, and brick output, so the power consumption is minimal.Only when it needs to work, the whole motor starts to operate, so the energy saving rate can reach about 25-45%. Energy saving means saving electricity, so that the electricity bill of a single device can save tens of thousands of yuan a year.

The pressure sensor is a device used to measure pressure changes in the hydraulic system. It can convert pressure changes into electrical signals and feedback to the main pump through the control system, thus achieving adjustment and control of the hydraulic system. The control system usually consists of electrical components, sensors, PLC (Programmable Logic Controller) and other parts, which can monitor the machine's operation status and parameters in real-time, and automatically adjust and control the machine according to design requirements.

Adjusting the density and strength of bricks requires controlling the pressure in the hydraulic system. When the pressure of the hydraulic oil increases, the pressure in the hydraulic cylinder also increases, which can increase the density and strength of the formed bricks. Conversely, when the pressure of the hydraulic oil decreases, the density and strength of the formed bricks will also decrease accordingly. Therefore, by adjusting the pressure in the hydraulic system, the density and strength of the bricks can be controlled.