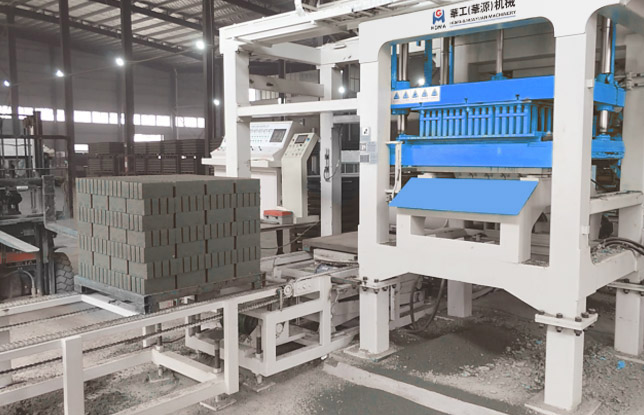

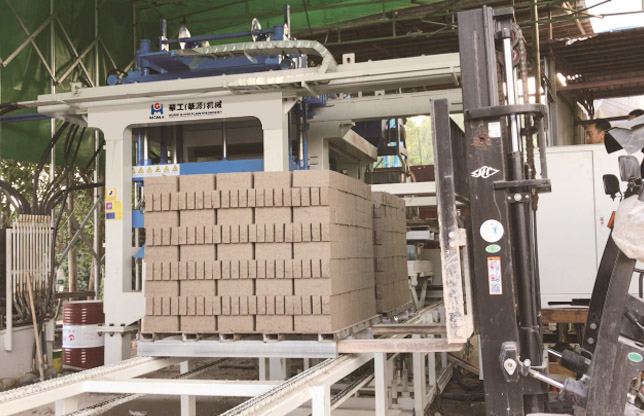

HGT8-15 Pallets-free Brick Machine is fully automatic It can be palletized immediately after forming,Save time, save labor;

1、No pallets are needed, can be palletized immediately after forming, saving the time and cost of pallets' loading and unloading.

3、The skip car is designed with double deceleration motor, and the material is agitated quantitatively by rotating at the same time. The material distribution speed is fast and uniform.

5、Products are more compact and uniform.

8、The equipment runs more stably.

Leave A Message

Leave A Message