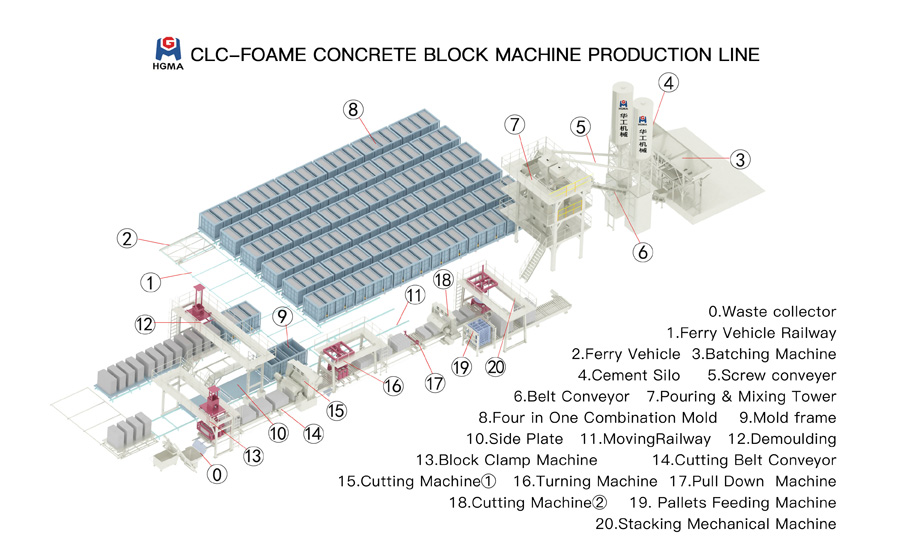

This set of equipment is used for producing load-bearing ceramsite reinforced aerated block and non load-bearing self insulation foam concrete brick, as well as external wall insulation board and fire door core board. The investment of the whole production line is small, which is only 20% to 2% of the traditional production line (high-pressure steam curing), with low production cost and low operation cost.

Features of hgma cement foaming block machine:

1. The production line of ceramsite block can be arranged according to the actual site of the customer's factory, and the specifications of ceramsite brick can be customized.

2. The automatic correction device is used in the whole cutting line in the process of operation, so that the ceramsite brick production process will not appear offset, tilt and other cutting errors, to ensure a higher yield.

3. Hengxing machinery's Ceramsite aerated block equipment can make the ceramsite block automatically take off the film and feed automatically.

4. The ceramsite block cutting machine produced by Hengxing machinery implements automatic cutting of ceramsite aerated block, automatic feeding of assembly line operation, automatic completion of multiple cutting, automatic stacking of finished products, with high degree of automation.

5. Hengxing machinery can design waste water recycling system in ceramsite block cutting production, so as to achieve zero waste discharge and green production in ceramsite block cutting factory.

CLC-Foam Concrete Block Machine Main Technical Parameters (six-sided cutting)

|

Category name Model Quantity |

80,000 m³ |

160,000 m³ |

|

Quantity |

Quantity |

|

|

Material system |

||

|

Powder can |

35m³ 2 pcs |

60m³ 2 pcs |

|

Screw conveyor φ219 |

2 lines |

2 lines |

|

Mixing and pouring system |

||

|

Special mixer for pouring |

Capacity V=3.5m³ 15kw 2 sets |

Capacity V=3.5m³ 15kw 2 sets |

|

Metering system |

Water measuring scale 1 set (2000kg) |

Water measuring scale 1 set (2000kg) |

|

Powder weighing scale 2 sets (1000kg) |

Powder weighing scale 2 sets (1000kg) |

|

|

Additive weighing scale (50kg) |

Additive weighing scale (50kg) |

|

|

Foaming system |

1 set |

1 set |

|

Mould conveying and transfer system |

||

|

Shuttle bus 2.2kw/set |

2 set |

2 set |

|

Ferry track |

2 lines |

2 lines |

|

Walking track 6m/piece |

6 lines |

12 lines |

|

Mould 2 m³/pair |

140 pcs |

280 pcs |

|

Hydraulic die feeding machine4kw/set |

5 set |

10 set |

|

Stripping machine 10.0 kw |

1 set |

2 set |

|

Cutting system |

||

|

Hanging machine 5.5 kw |

1 set |

2 set |

|

Block cutting machine 8.2 kw |

1 set |

2 set |

|

Assembly line cutting machine 22kw |

1 set |

2 set |

|

Assembly line cutting machine 2 30kw |

1 set |

2 set |

|

Pipeline cutting machine three 7.5kw |

1 set |

2 set |

|

Pull down machine 5.5kw |

1 set |

2 set |

|

Pipeline cutting machine four 15kw

|

1 set |

2 set |

|

Finished product palletizer (displacement stroke 3m, lifting stroke 1.4m) |

1 set |

2 set |

|

Microcomputer control system |

||

|

Pouring control system 1 set Mold control system 1 set Cutting control system 1 set |

PLC is Japan Mitsubishi, proximity and travel switches are Japan Omron, contactors and buttons are France Schneider, touch screen is Taiwan WEINVIEW |

|

Leave A Message

Leave A Message